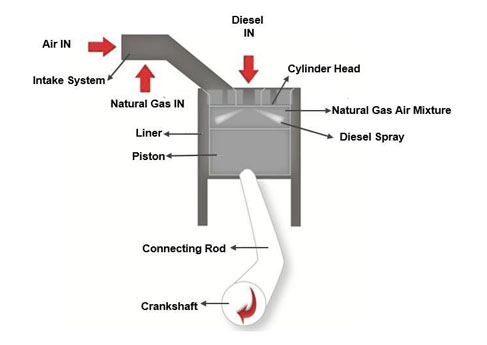

Introducing the Cummins Dual Fuel Conversion Kit – Revolutionize Your Engine Efficiency and Savings! Are you looking for an innovative solution to reduce fuel costs and lower emissions without sacrificing performance? Look no further than the Cummins Dual Fuel Conversion Kit. Designed specifically for diesel engines, this cutting-edge technology allows you to seamlessly transition to a cleaner and more cost-effective fuelling option. With the Cummins Dual Fuel Kit Conversion Kit, you can enjoy the benefits of both diesel and natural gas, maximizing your engine efficiency while significantly reducing your operational expenses. By leveraging the power of natural gas alongside diesel, you can achieve substantial fuel savings without compromising on power output or engine reliability. Our conversion kit is engineered with precision to deliver seamless integration and optimal performance. The advanced control system ensures precise fuel delivery, maintaining the perfect balance between diesel and natural gas to achieve the highest levels of efficiency. The result? Reduced fuel costs, lower emissions, and a positive impact on your bottom line. In addition to the financial benefits, the Cummins Dual Fuel Conversion Kit also helps you meet environmental regulations of CAQM. By reducing your carbon footprint and decreasing harmful emissions, you demonstrate your commitment to a greener future while adhering to the statutory compliances of CAQM. Don’t miss out on this opportunity to optimize your engine’s performance and drive your business towards a more sustainable future. Contact us today to learn more about the Cummins Dual Fuel Conversion Kit and how it can transform your operations.